Why choose us?

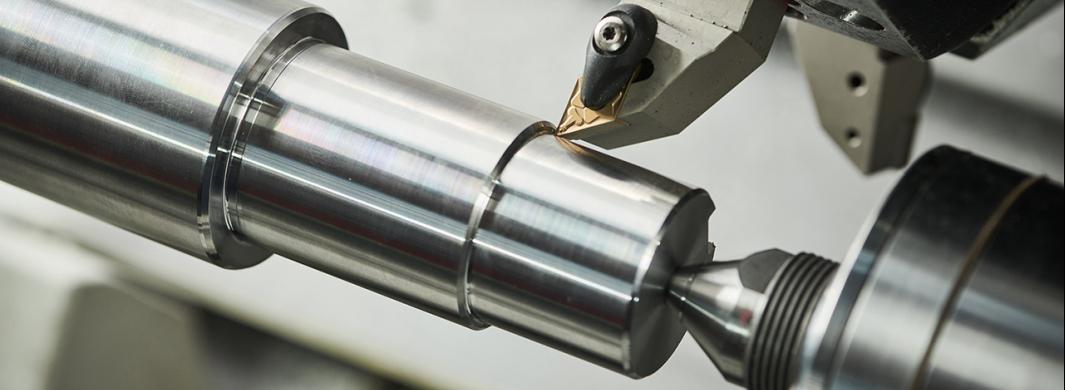

A single point of contact for the entire production chain. Because you will have a single reference across all production phases, from precision mechanical machining to sheet metal processing, gear cutting, and surface and heat treatments, with concrete benefits in terms of simplification, time, and operational management.

Experience and reliability in every field

Because each company in the group has been operating in its reference sector for years, providing consolidated expertise, suitable technologies, and qualified personnel in the specific processes.

The complementarity of technical profiles ensures solidity and reliability at every stage of the process.

Coordinated management of complex projects

Because the management of complex projects is facilitated by the presence of a common temporary manager, allowing us to handle complex orders by fully integrating the technical and organizational know-how of the various companies in the group.

Co-design

Thanks to technical offices with many years of experience gained in various sectors, with our group, customers can count on a unique asset for co-design. This means having a partner that integrates cross-disciplinary skills and provides concrete support for customer needs, simplifying choices and enhancing projects with dedicated co-design. In the event of specific technical requirements, we also have the option of calling on engineering firms that collaborate continuously with our consortium and are able to support us in developing complex projects.

PRESS BENDING

WELDING

POWDER COATING